Sign Design and Engineering

• Sign Design and Engineering – From Concept to Construction

• The Design Journey

• The Engineering Backbone

• Permits and Compliance – Handled In-House

• Bringing It All Together

• Frequently Asked Questions

• Ready to Start Your Project?

Sign Design and Engineering – From Concept to Construction

When people think about a new sign, their first concern is usually design: What will it look like? Will it fit our brand? Will it catch attention? At Sun Sign Company, we believe design is the heart of every successful sign—but design only works when it’s paired with robust engineering that guarantees safety and longevity. Together, these two disciplines transform an idea into a landmark.

The Design Journey

We treat design as a collaborative process. It starts with conversation and ends with a fully realized plan for your brand’s visibility, legibility, and impact.

-

Artwork & Branding – Fonts, colors, logos, and layouts are chosen for clarity, viewing distance, and night/day contrast. We design for brand consistency and quick recognition.

-

Scaled Renderings – Full-color proofs, dimensioned drawings, and photo simulations show your sign in context before fabrication begins.

-

Revisions & Approvals – We iterate until the look, scale, and placement are right. Nothing moves forward without your approval.

-

Fabrication-Ready Files – Clean, production-grade artwork with accurate line weights, kerning, and bleed/margins ensures a seamless handoff to manufacturing.

The Engineering Backbone

Once the design is finalized, the unseen but vital work of engineering begins. This is where safety, compliance, and longevity are built in.

-

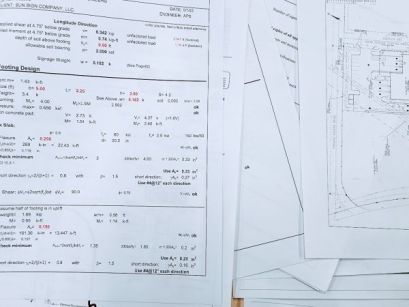

Structural Calculations – Poles, cabinets, and footings are engineered for regional wind exposure, overturning moments, and serviceability. We account for soil bearing capacity, embed depths, anchor bolt patterns, and weld sizes.

-

Load Cases & Connections – We consider dead loads, wind suction/pressure on faces and cladding, and connection detailing (gussets, baseplates, fillet/complete-joint penetration welds) for long-term performance.

-

Materials & Corrosion Protection – Specified steels, fasteners, and coatings are selected for outdoor duty cycles, including galvanization or high-solids coatings where appropriate.

-

Validation & QA – Fabrication and installation follow engineered drawings. Dimensions, bolt torque, plumb/level, and foundation cure times are verified against plan.

Engineering is what ensures a towering pylon remains stable in a storm and that channel letters stay secure after years in the elements. It’s precision applied to creativity.

Permits and Compliance – Handled In-House

Sun Sign Company manages permits and engineering in-house across Ohio, Kentucky, and West Virginia, streamlining approvals and reducing delays.

-

Zoning & Code Review – We verify allowable heights, setbacks, and illumination rules for your jurisdiction.

-

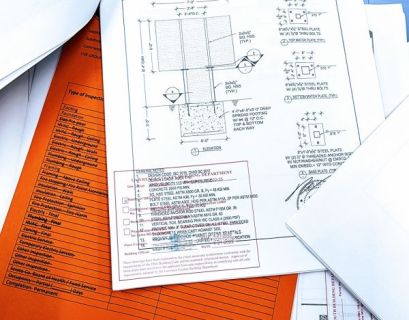

Permit Drawings & Submittals – Dimensioned site plans, elevations, and structural sheets prepared for municipal review.

-

Inspections & Closeout – Coordination with inspectors from foundation to final to ensure a smooth sign-off.

Bringing It All Together

Turning artwork into a functioning structure is both creative and technical. With Sun Sign Company, design captures attention, engineering guarantees performance, and permitting clears the way—so your sign looks exceptional and stands the test of time.

Frequently Asked Questions

How involved will I be in the design?

You’ll review proofs, drawings, and renderings at each step. We proceed to fabrication only after you approve the design.

Can you create artwork from scratch?

Yes. Provide a logo or a rough idea, and we’ll develop professional artwork optimized for readability, materials, and illumination.

Do you handle permits in my town?

Yes. We manage permitting and engineering in-house for communities across OH, KY, and WV—applications, drawings, inspections, and final sign-off.

What makes your engineering different?

We account for wind exposure, frost depth, soil type, and material tolerances. Connections, welds, baseplates, and anchor systems are detailed for durability and serviceability.

Can I see how the sign will look before it’s built?

Absolutely. You’ll receive scaled drawings and photo renderings that show the sign’s size, placement, and sightlines on your property.

Why do design and engineering need to work together?

Design earns attention; engineering ensures safety. Blending both produces a sign that’s beautiful, code-compliant, and built to last.

Ready to Start Your Project?

Whether you’re envisioning a towering pylon, a refined monument sign, or custom channel letters, Sun Sign Company will take your project from concept to completion. We design, engineer, and handle permitting in-house across Ohio, Kentucky, and West Virginia—so you can focus on running your business while we bring your vision to life.

Request a Quote Today or Browse Our Portfolio of Completed Projects to see what’s possible.